Gases the easy way – Messer provides solutions - Strategic application technology

Breadcrumb

Customer segment Sulphite process

Sulphite process

Chemical pulp cooking with bisulfite

Sulphite process paper

Sulphite process paper

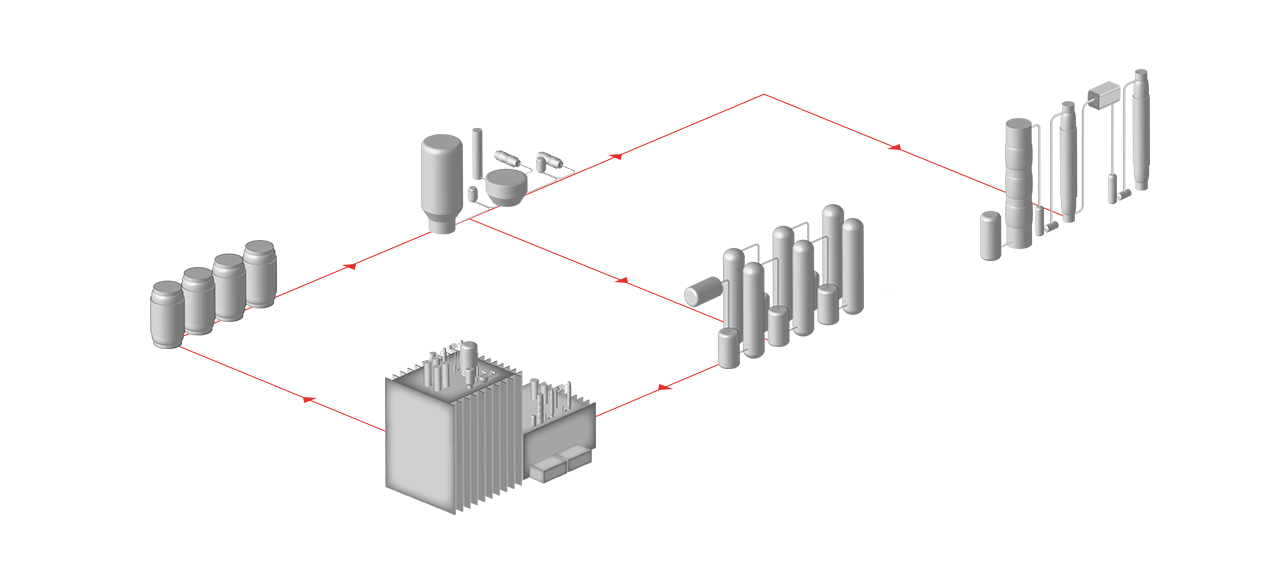

The sulphite process is an industrial process to produce wood pulp suitable for wood low in resin and silicic acid.The advantages of this process are above all the very efficient delignification, the good bleachability, the high reactivity during further processing and low investment costs. In the sulphite process, the wood fibres are digested in an acidic or neutral medium. In the process, the lignin is subjected to sulphonation and is thereby converted into a water-soluble salt which can be removed from the cellulose. The by-product lignosulphonates are either commercially recovered or incinerated (recovery). In case of recovery the black liquor separated from the fibres during pulp washing is evaporated and burned in the recovery boiler using oxygen. The very light pulps produced in this way are today used almost exclusively for the production of chemical cellulose or paper. To produce one tonne of pulp you need about five cubic metres of wood and 90 kilograms of sulphur.

Contact

Application technology startpage

GAS APPLICATION TECHNOLOGIES

Productivity increase, production throughput and ecological improvement with gases, expertise & know-how, onsite trials, research and development, commercial offers

Contact form for every page

Contact us

select action