Gases the easy way – Messer provides solutions - Strategic application technology

Breadcrumb

Customer segment Copper

Copper production

Global copper demand will increase from 23.6mnt in 2018 to 29.8mnt by 2027

Copper smelting and refining process

Copper smelting and refining process

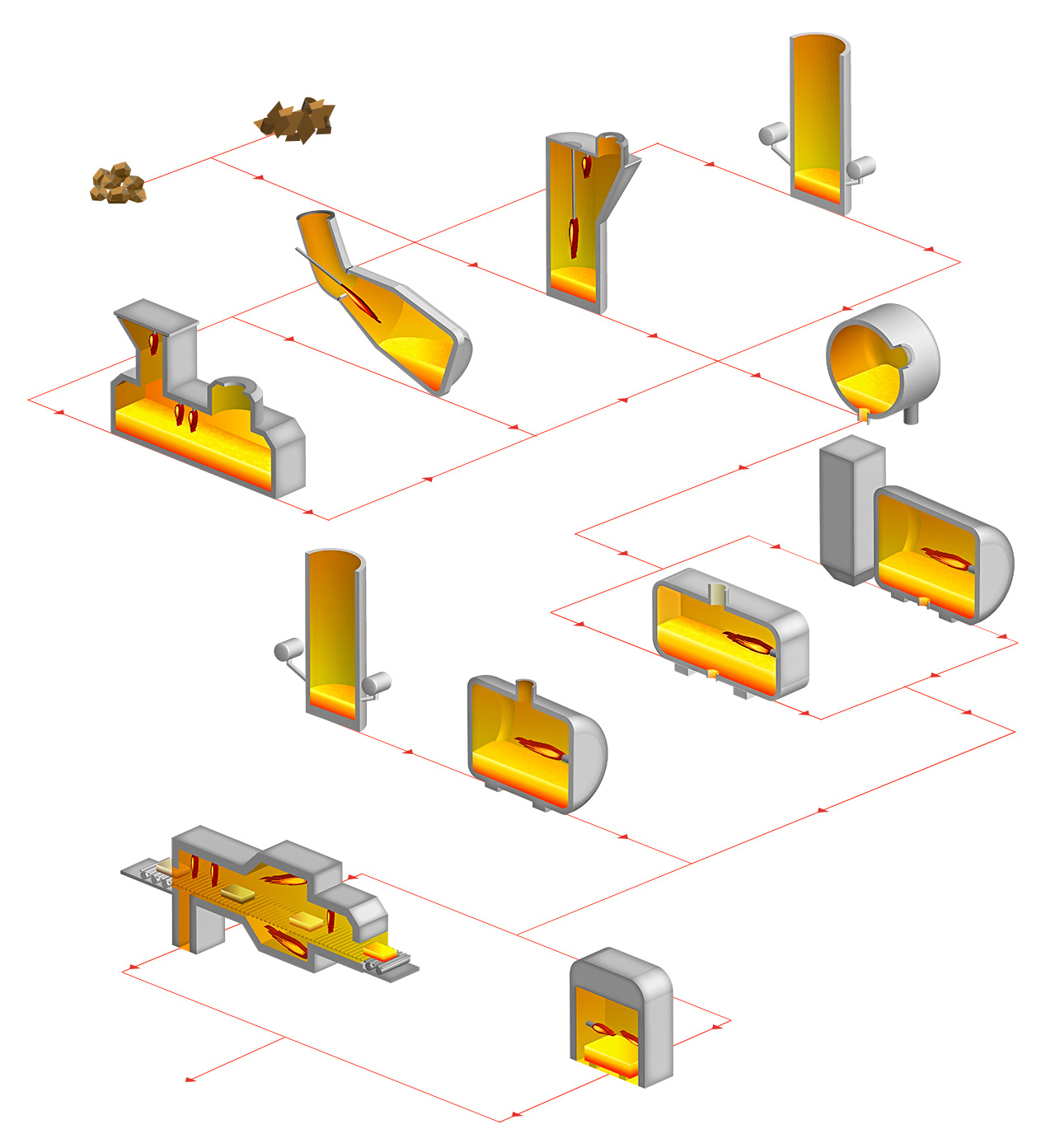

Copper production is carried out over several stages. Copper is either produced from copper ore (primary copper) or copper scrap (secondary copper). During primary copper manufacture, copper concentrate is used and reduced to blister copper after roasting. For secondary copper production copper scrap, slag, dross, dust or slurries are melted together with coke and slag-forming additives.

Various smelting processes are used. The resulting liquid copper matte (Cu 60 to 65%) is processed to blister copper (Cu approx. 98%) in a convertor. After fire-refining in anode furnaces the Cu purity is over 99%.

Single-origin scrap of a high purity is used for the production of wire and pipes using a direct smelting process with special shaft furnaces and immediately cast.

Heat treatment can modify the material structure and other properties of copper and adapt it for its intended use. Various furnaces such as batch type or continuous type furnaces are available for these processes. Bell furnaces are used for the final treatment.

Application proposal Solution proposal

Contact form for every page

Contact us

select action