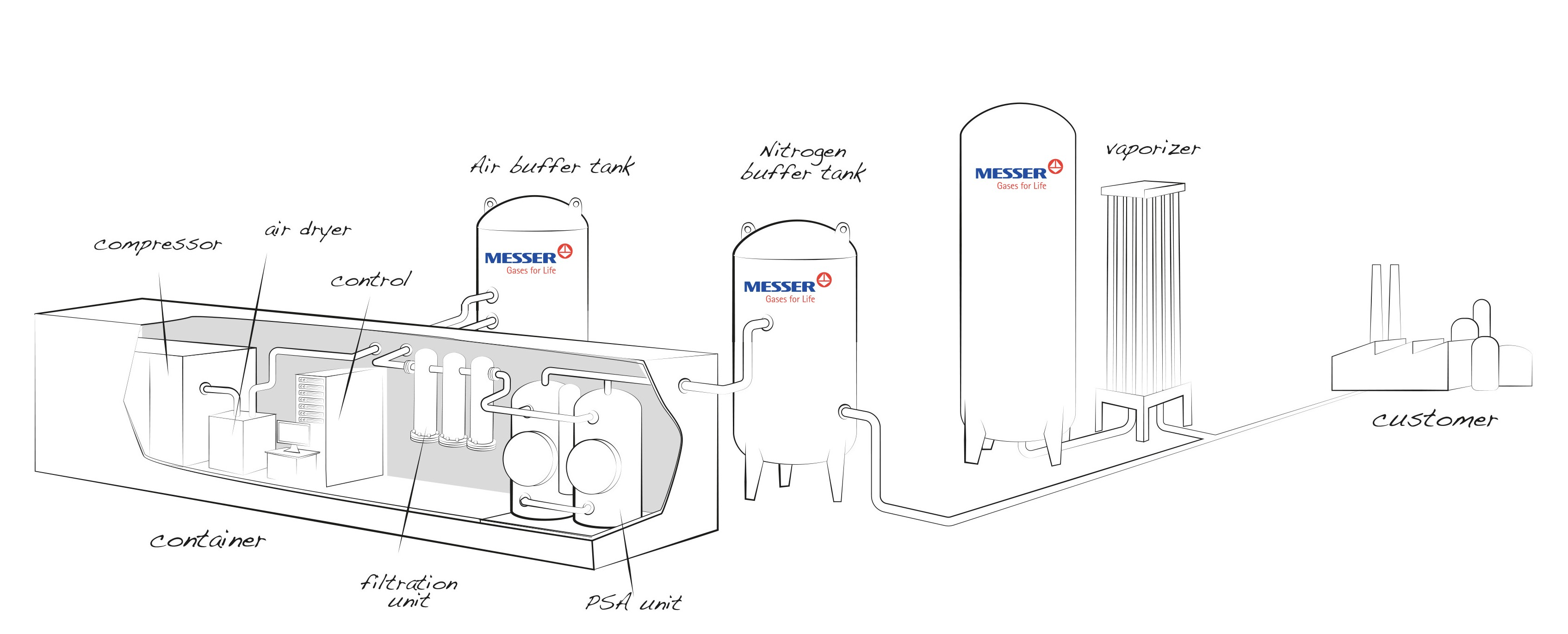

Flow diagram for the PSA unit - Strategic application technology

Breadcrumb

Customer segment oil & gas refering

OIL AND GAS REFINING

Improve productivity & get more ecological processes with gases

Oil and Gas Refining

Oil and Gas Refining

By definition, crude oil and natural gas are the raw materials of the petrochemical industry, with inert gases such as N2 and CO2 already used on a large-scale during their extraction. The processing of crude oil to the desired end products involves several steps. Again, gases from Messer are used in many of these process steps.

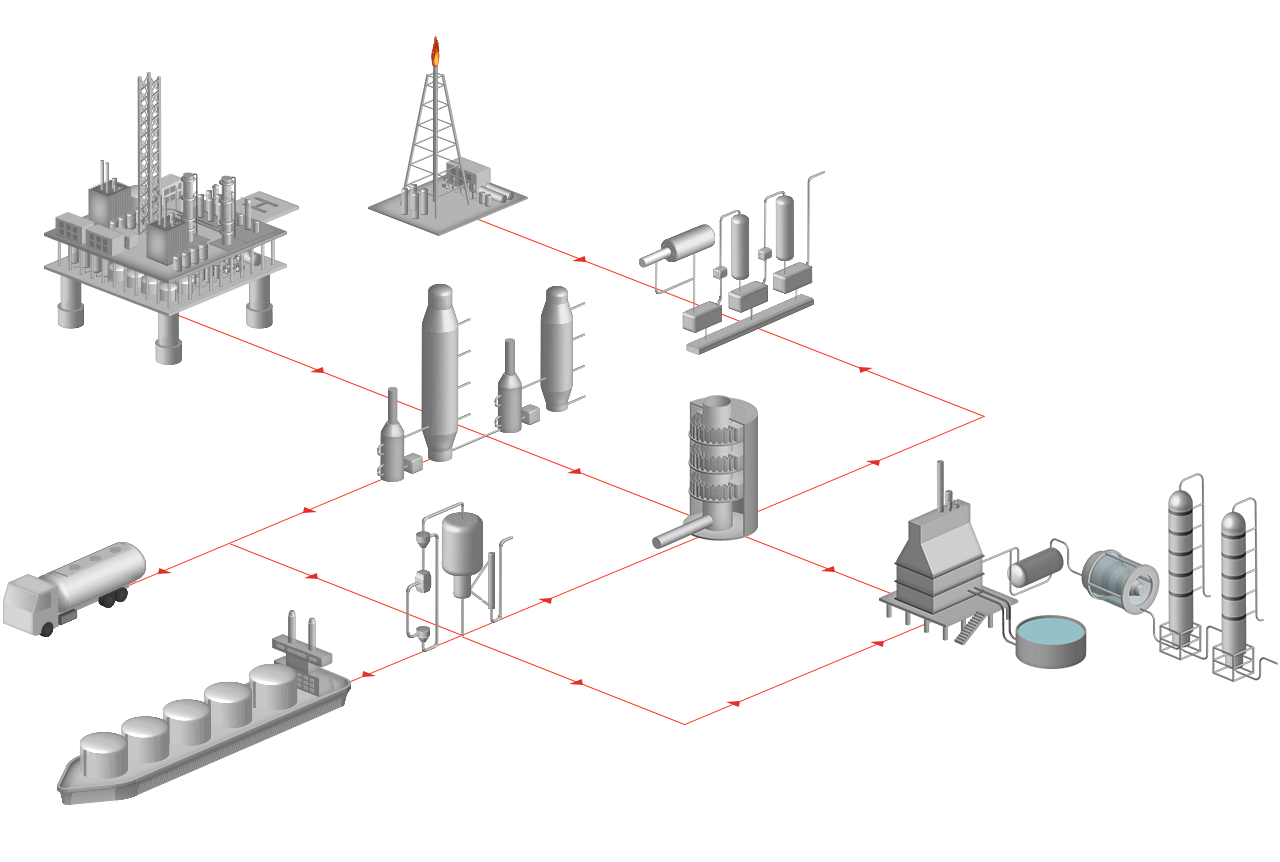

Customer process for oil and gas refining

Fluid catalytic cracking FCC

Major material conversion process in the oil processing industry

Leaflet

Asset Publisher

Dr. Nina

van Gellecom

Manager Chemical applications

Joachim

Rohovec

Senior Manager Chemical & Environmental applications

Other interesting topcis

Cracking of persistent COD with ozone

Equipment, expertise and gas for a complete solution

Contact

Dr. Nina

van Gellecom

Manager Chemical applications

Asset Publisher

Flow diagram for the PSA unit

Application technology startpage

GAS APPLICATION TECHNOLOGIES

Productivity increase, production throughput and ecological improvement with gases, expertise & know-how, onsite trials, research and development, commercial offers

Contact form for every page

Contact us

select action