Gases the easy way – Messer provides solutions - Strategic application technology

Breadcrumb

Customer segment Frit and color pigment

Frit & Color pigment

The material for surfaces

Frit and color pigment

Frit and color pigment

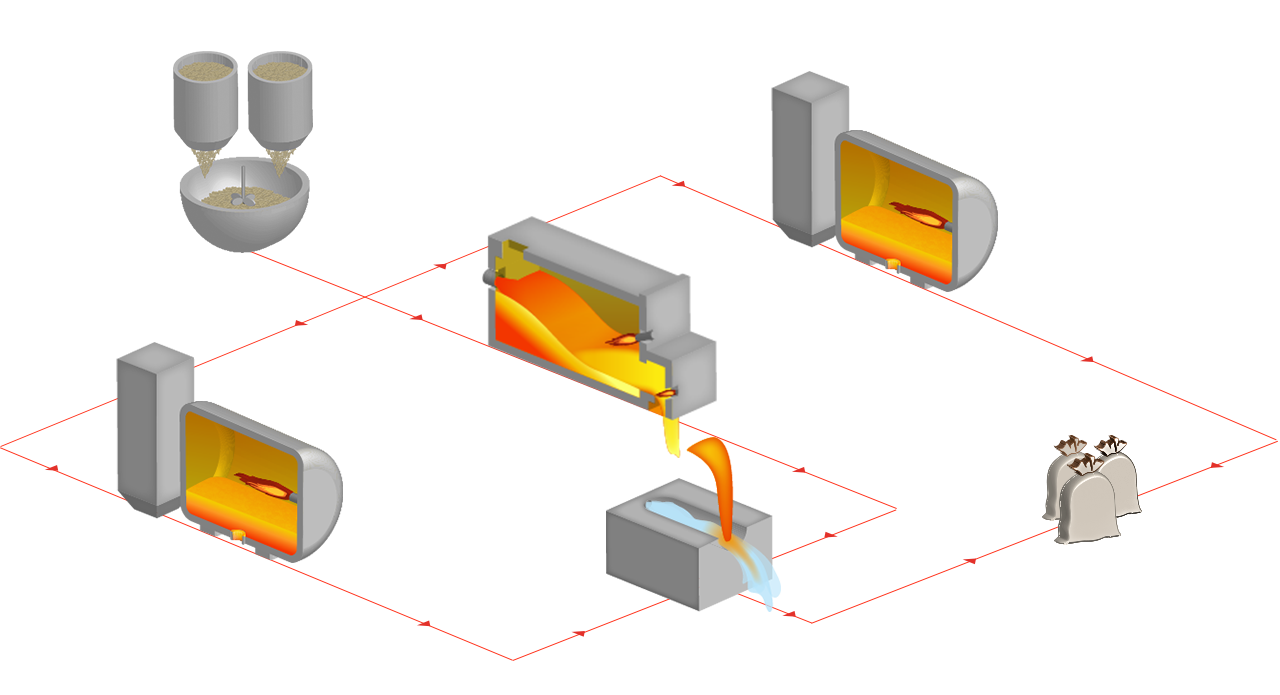

In the frit- and mineral colour pigment production, the raw materials of the batch are generally stored in silos. Based on the recipe the components are charged into a mixer in a pre-defined order to eliminate separation. The mixed batch is then transported to the batch charger – usually of screw type – and fed, in a certain amount for each charge, to a smelting aggregate, which may be a hearth furnace or a rotary furnace . In case of colour pigments, the smelting aggregate is generally a rotary furnace. The batch is melted in a melting area what can be air-fuel or oxy-fuel fired. After a pre-defined melting time, the material is withdrawn from the furnace through a heated throat (in case of a hearth furnace) or poured out from the drum of the rotary furnace and quenched with water on a chute or a conveyor . The powdery product is collected in big bags or – after performing a drying measure out into a paper bag.

In case of frit we distinguish three different types:

a. Ceramic/glass frit

b. Enamel frit

c. Low melting point frit

The major components, depend on the different types of frit, are:

- Feldspar, sand, calcium carbonate, dolomite, zinc oxide, zirconium compounds for ceramic/glass frit

- Sand, borax, titanium oxide, sodium nitrate and different fluorides for Enamel frit

- Red lead (Pb3O4), sand, zinc oxide, boric acid for low melting point frit

Onsite gas production

ONSITE GAS PRODUCTION - OXYGEN, NITROGEN, CARBON DIOXIDE, HYDROGEN AND MORE

Onsite supply concepts – Customer installations – Liquid backup storage tanks – Telemetry options – Turn key solutions – Application technology advise - Commercial offers

Contact form for every page

Contact us

select action